Associated Plant AGMAN Inc. (Turkey) – 2018

Introduction to Agman Inc.

Agman Inc. was founded in 2013. The first plant, Agman Ovacık Biomass Energy, produces electricity and digestate at the Lüleburgaz Kirklareli biogas plant.

Beginning as a group company since 2016, Agman A.Ş has been expanding its biogas production to supply more electricity for domestic use. Agman provides all projecting, engineering, construction, and commissioning and operational consultancy related to their biogas plants.

Current process

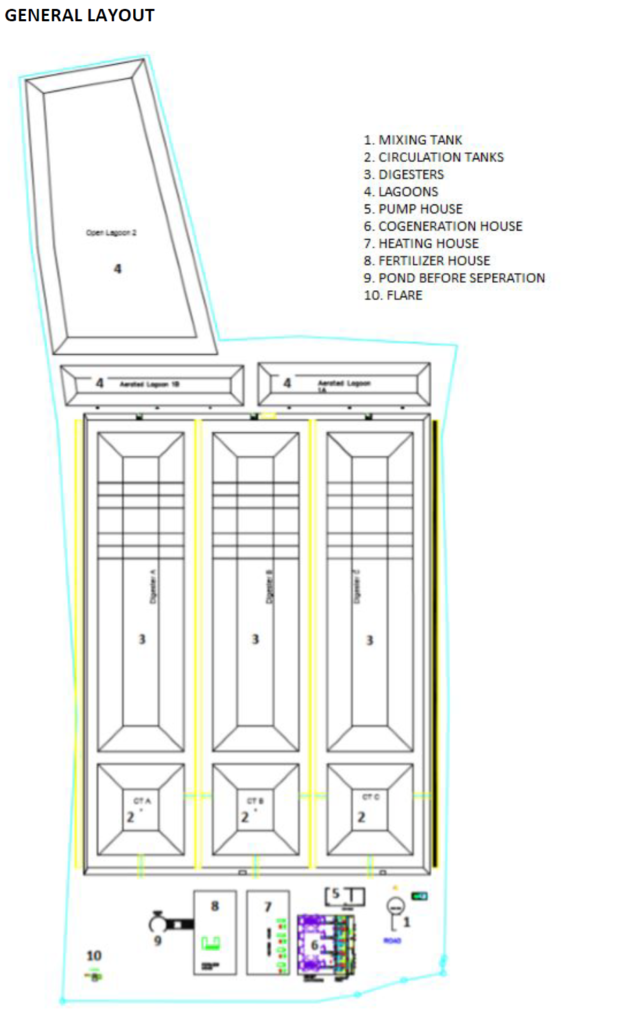

In their biogas plant in Lüleburgaz, Kırklareli, has 3 lagoon-type digesters from Chinese design. These digesters are rectangular-shaped (100m long – 50 m wide and 12 m deep). Two of them are covered and third one will be covered in summer 2018. The plant has a 4,8 MWel maximum capacity, 4.4 MWel continuous capacity and capacity to convert 21.199.200 m³ of biogas per year into 35.332.000 kWh electrical energy per year and 36.732.000 kWh of heat per year.

The digestate is stored in open lagoons and separated by precipitation in a separator pond. After the seperation unit remaining liquid fraction of the digestate contains 2% suspended solids.

End products

8 ha of land include the biogas plant and the surroundings and this is used for spreading of 14.600 tonnes of solid fraction of digestate per year and 219.000 tonnes of liquid fraction of digestate per year.

The digestate(products) currently don’t have a market value.

Pressure and problems

Agman produces a lot of digestate (233.600 tonnes per year) and has difficulties in disposing these volumes.

This is because, in Turkey, farmers do not have strong know-how regarding the use of digestate (liquid) as a fertilizer. It is a big challenge to convince farmers to spread the digestate as fertilizer on their fields instead of commonly used (chemical and organic) fertilizers. This causes waste management problems in biogas plants.

One of the open lagoons is used to store digested manure before it is send to the separator pond. There is no specific ammonia removal/air cleaning at this point.

Since no more poultry manure is digested, Agman assume that ammonia emission from the digestate is limited.

A second problem is the high concentration of H2S of the digestate. Agman have built one chemical and one biological cleaning tower. Ca(OH)2 is used for chemical treatment. Our aim to decrease H2S amount under 100 ppm. Agman is looking for technical optimisation of the current H2S removal.

Opinion Agman on nutrient recovery and vision for creating better marketable products

- Investigate different technologies to improve their current way of digestate disposal and H2S removal.

- Stimulate the usage as a fertilizer to replace the current mineral fertilizer use of the farmers.

Dry farming is a common practice in Turkey. This is cultivation of crops that don’t need a lot of water like sunflower, wheat, barley. Therefore, it will be investigated if the liquid fraction of the digestate would be accepted by the farmers as a nutrient rich alternative for water.

Next step is to see if a digestate product could be made with a higher fertilizing value (more concentrated NPK).

This could also create a price for the digestate(products) which is not the case at the moment. For their plant, this would also be a first step into the direction of circular economy.

Actions AGMAN in SYSTEMIC

Completed

- To learn how other biogas plants are dealing with these issues, Agman has applied to be an Associated plant in the SYSTEMIC project.

- Attend the Kick-off meeting of Living Labs in Amsterdam on 22-23th February 2018

- Meeting with Dr Oscar Schoumans at Wageningen and visit to Biogas Bree in Belgium.

- Asked some questions regarding nutrient recovery to the SYSTEMIC consortium

Read more about it in the report: Associated Plant AGMAN visits Biogas Bree.