Associated Plant AGMAN Inc visits Outreach Location Biogas Bree – 2018

21 of March 2018 representatives from AGMAN Inc. visited Dr Oscar Schoumans, projectcoordinator of SYSTEMIC and Outreach location Biogas Bree.

Learnings AGMAN from Biogas Bree

Technologies to reduce their digestate volume are very interesting for Agman.

Therefore, the home-made evaporation system of Biogas Bree was discussed. Biogas Bree uses the heat from the biogas in the evaporator to increase the dry matter in the raw manure and to heat up the digesters.

The biogas treatment was also discussed. Biogas bree cleans its gas with iron oxide.

Learnings from meeting with Oscar Schoumans (WUR)

The topic of separation of the digestate was discussed with focus on obtaining enriched N-P-K fertilizers.

Future plans

Due to the feedstock combination (vinasse), Agman decided to go for a three phase H2S cleaning of the biogas:

- biological sulphur precipitation by adding O2 (0,5-1,5% in gas phase)

- biological scrubber utilizing H2S bacteria

- Chemical blend with CaOH with H2S

Tests has been conducted and 150 ppm H2S levels have been achieved.

Before investing in full scale nutrient recovery, the first goal is creating a market for the digestate in liquid and dried form as Agman is located in an agricultural area where there is a high demand for fertilizers.

For application of the liquid fraction of the digestate, Agman will look into buying liquid fertilizer distribution tanks, which can be attached to the back shaft of the tractor. For this purpose Agman has joint forces with the Local Office of the Ministry of Agriculture in Kırklareli in order to improve the nutrient quality in grazing lands for animals.

Questions for the SYSTEMIC consortium (May 2018)

AGMAN: Which fertilizers could be Could it be possible to predict how much nutrient will be recovered from the input? If yes, are there calculations for it?

SYSEMIC: In SYSTEMIC we will develop a tool that gives you the nutrient recovery rate for different recovery technologies and types of digestate. The tool will be based on literature and data from the plants, and recovery is also very much determined by the composition of the digestate (e.g. the input of the digester). Therefore, this tool will only give you an idea or estimation on how much nutrients can be recovered in certain end products.

I realized that there is no theoratical solution for nutrient recovery. We can say that it is possible to recover 45-60% of N, 80-90% P and 35 – 50% K from the digestate but we are very much dependent on the technology.

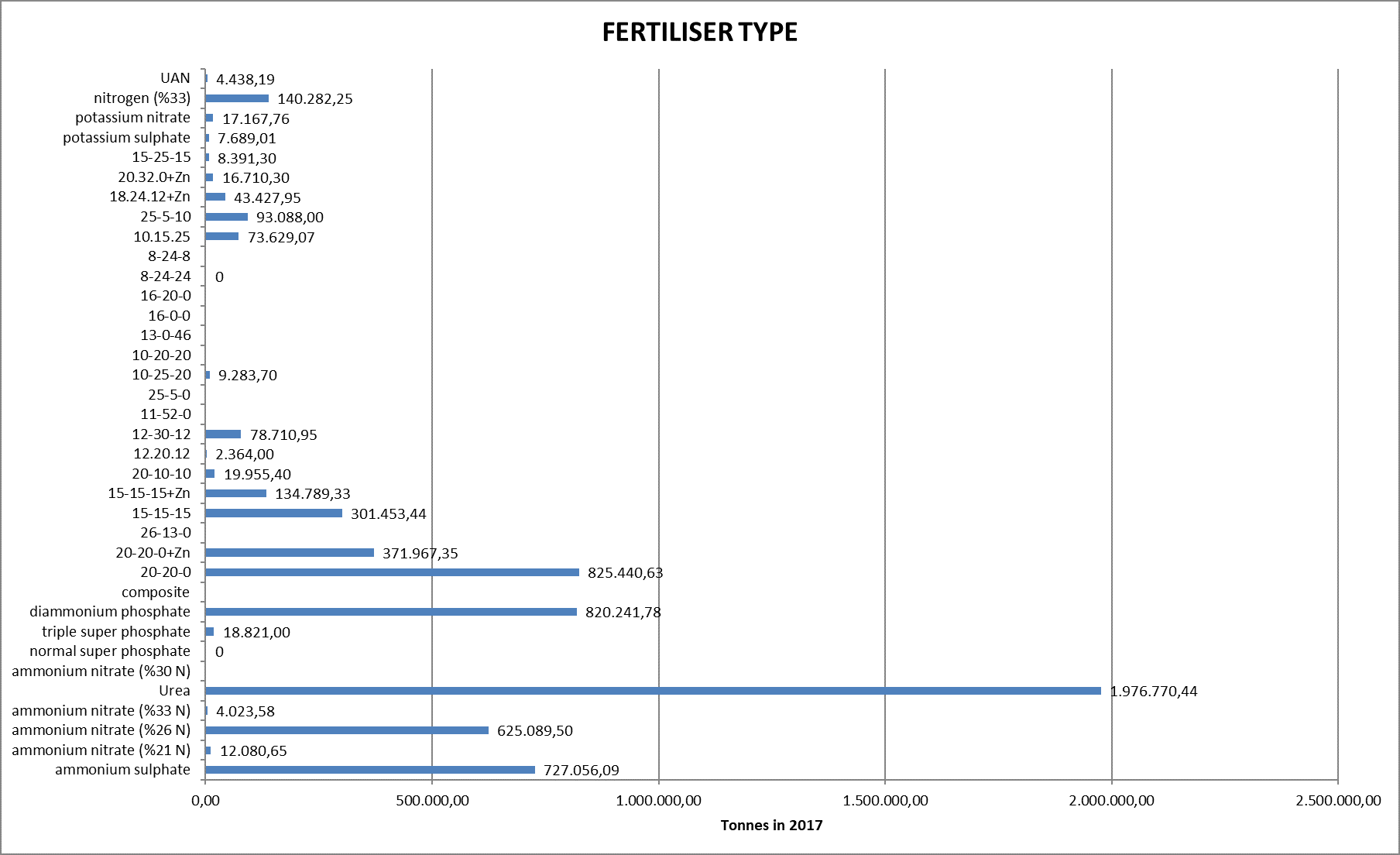

Which end products would be interesting for us to make? Below you can find the Turkish fertilizer market report.

Urea is one of most popular fertilizers among the Turkey. However, we are looking into making NPK fertilizers such as NPK 15-15-15, 20-20-20 and etc. Those percentages do not need to be exact. it could be less or more. And NPK values could differ to. Ex: NPK 16-8-5. This means that we have figure out a technology that can recover those amounts from the digestate. I believe that if we could recover similar values of mineral fertilizers that are being sold on the market, that might make marketing efforts easier.

If you would like to make tailor-made products in which you can determine the nutrient content you will have to try to achieve an efficient separation of the digestate into P and organic matter rich fraction, N rich fraction and water. To what extend you would like to achieve this is up to you. A simple way of separating the larger amount of P and organic matter from nitrogen and salts is by means of a centrifuge. The solid fraction will normally contain most of the organic matter, phosphorus and the organic nitrogen. The liquid fraction will contain the soluble nitrogen (ammonium) and salts (potassium).

The solid fraction can be dried (to reduce volume for transport) or spread on land as P fertilizer rich in organic matter (which is a great soil conditioner).

The liquid fraction could be further valorised by ammonia stripping/scrubbing, hereby creating an ammonium sulphate or ammonium nitrate solution, which is comparable to mineral fertilizers. It will probably have some more organics than mineral fertilizers.

The ammonia stripped liquid will still contain salts, but this can be a good fertilizer for certain crops.

All these separate nutrient products can be blended to tailor-made fertilizers but their marketability depends on the quality you’ll produce and of course your marketing strategy.

The challenge will be to produce products that are easy in application (and have low emissions) and to convince farmers that your recovered products have the same agronomic value as mineral fertilizers.

On agronomical value of these products, we can provide you scientific results from literature, but it is the marketing strategy that will determine if you can ask a good price for your recovered products.