About

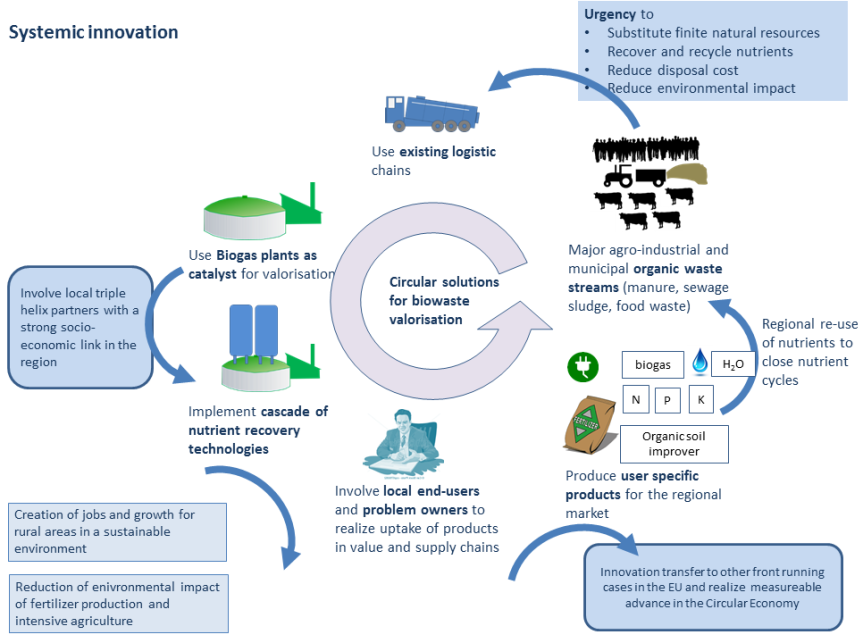

SYSTEMIC is a project funded under the EU Framework Programme for Research and Innovation H2020 for the period 2017-2021. SYSTEMIC recognises Europe’s challenge to tackle the increasing resources constraint and to facilitate the transition towards a more circular economy (COM,2015-614). SYSTEMIC addresses these needs by identifying systemic innovation approaches to recover and recycle valuable mineral components from organic waste streams into new products and to integrate them optimally into a local or regional circular economy.

CHALLENGE

Bio waste, like animal manure, sewage sludge and food and feed waste, form the most abundant waste stream in Europe and hence, the most prominent potential resource for the production of bio gas and the recovery and reuse of mineral nutrients like phosphorus (P), nitrogen (N) and potassium (K). Nowadays, they are often not being recovered, posing severe challenges in terms of inefficient resource use, disposal and environmental pollution mainly because the composition of those bio waste resources does not meet the crop requirements.

URGENCY TO CLOSE NUTRIENT CYCLES

NON-RENEWABLE RESOURCE USE

The production of nitrogen (N) and phosphorus (P) mineral fertilisers currently requires on one hand non-renewable resources (finite P rock) and the use of natural gas (to produce N fertilisers from N2 in the air), while on the other hand significant amounts of N and P are available in waste streams which can be recovered and reused.

BIO WASTE DISPOSAL AND REUSE

Large amounts of bio waste and manure have to be transported over large distances from regions with surpluses to regions with a demand for nutrients. Besides leading to high CO2 emissions and high transport and disposal costs, the transport of bio waste leads to the loss of valuable organic matter from regions with a mineral surplus.

ENVIRONMENTAL POLLUTION

Paradoxically, the excessive production and use of N and P biomass streams with inefficient N-P ratios also causes severe environmental problems, especially in regions with intensive livestock husbandry and high application rates causing leaching of nutrients to groundwater in drinking water supply areas and sophistication of water bodies.

GOALS

In recent years, multiple nutrient recovery and reuse (NRR) technologies have been developed and tested in pilot facilities and proven to be ready for implementation at large scale. SYSTEMIC has selected the most promising NRR technologies and aspires to implement these on five state-of-the-art anaerobic digestion demonstration plants in order to demonstrate that the combination of anaerobic digestion and nutrient recovery forms a prerequisite for the valorisation of bio waste in an economically viable manner.

By doing this, SYSTEMIC will:

INNOVATION & BENEFITS

SYSTEMIC’s concept for the development and implementation of region-specific circular solutions for bio waste valorisation and nutrient recycling:

SYSTEMIC will contribute to change our current predominantly linear nutrient management into one that contributes to the CIRCULAR ECONOMY.

Within a circular economy, biowaste is considered as a source of energy, organic matter and nutrients such as nitrogen (N), phosphorus (P) and potassium (K). These nutrients are valuable and, in the case of P, non-renewable. The recovered nitrogen (N) can be used to replace a part of the current production of synthetic N-fertilizers, thereby substantially reducing CO2 emissions associated with the production of synthetic N-fertilizers. The recovered phosphorus (P), an essential plant nutrient, can be used to replace current mineral P-fertilizers thereby reducing Europe’s dependency on external and non-renewable P-reserves. The remaining organic matter forms a valuable soil amendment that can be used in nearby regions, thereby substantially reducing CO2-emissions associated with transport.

Overall, this circular approach offers an economically viable solution for the processing of biowaste, while reducing CO2 emissions and preventing nutrient losses.

CONSORTIUM