Over 25 people joined a site visit to Groot Zevert Vergisting in Beltrum, the Netherlands on 16 May 2019. The visitors included biogas plant owners, manure processors, stakeholders from the fertiliser industry and academics from Flanders, Belgium, the Netherlands, Germany and further.

The site visit was organised in the framework of two projects: by VCM and Wageningen University & Research, partners in the Horizon 2020 project SYSTEMIC, together with Biogas-E, partner in the IWT/VIS project ‘Transbio’.

The guided tour and information were provided by responsibles from Groot Zevert Vergisting, Wageningen University & Research and Nijhuis Industries.

If you were not able to attend, you can watch the videos below (left: in English, right: in Dutch).

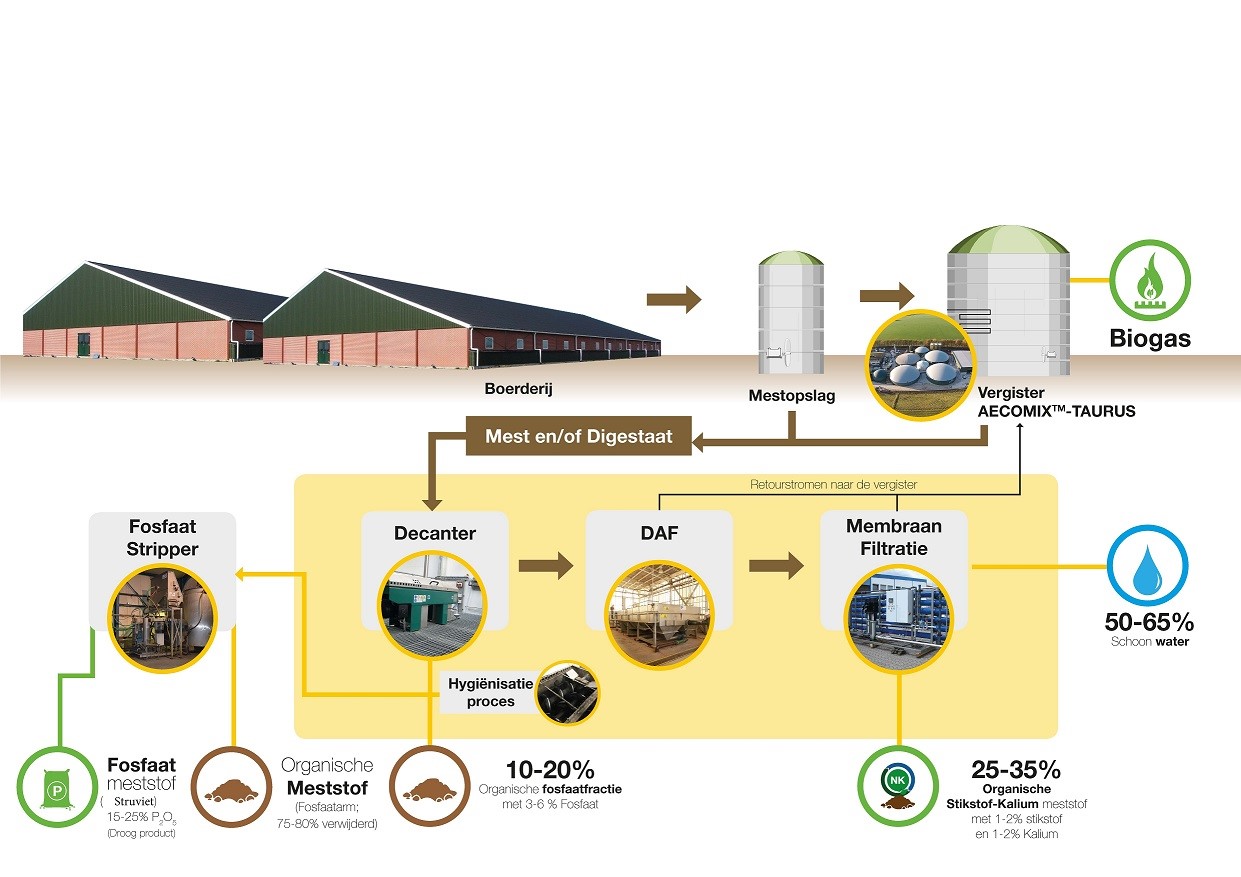

GENIUS: NK concentrates and dischargeable water

Suspended solids are further removed from the the liquid fraction through a Dissolved Air Flotation unit, by adding flocculants and fine air bubbles, catching the solids, grease and oil in a flotating layer of sludge.

In the following steps, the liquid fraction is treated with micro-filtration, a reverse osmosis and ion exchanger.

This renders two end products:

(1) water that complies with strict discharge limits and can therefore be released in the creek nearby;

(2) an NK concentrate.

The GENIUS process has been operational at Groot Zevert since March 2019.

In the framework of the pilot project ‘an Achterhoek without artificial fertiliser’ together with ForFarmers, this mineral concentrate is mixed with ammonium sulphate and/or ammonia water, to better comply with the crops’ nutrient demands. In 2018, field trials were done on grass and in 2019, on corn.

Within the 6th Dutch action plan, the pilot project ‘an Achterhoek without artificial fertiliser’ is allowed to use the NK concentrates (“Green Meddows Fertiliser”) on the fields of a limited amount of farmers for two years as ‘mineral fertiliser’, i.e. application of more than 170 kg N/ha.year through precicion injection.

The application and results of the field trials are carefully monitored by Wageningen University & Research. The results of agronomical efficacy, N efficiency and environmental leaching will be very valuable for the SAFEMANURE study. This is a project conducted by the Joint Research Centre, commissioned by the European Commission and will study the criteria required for the safe use of recovered fertilisers from manure.

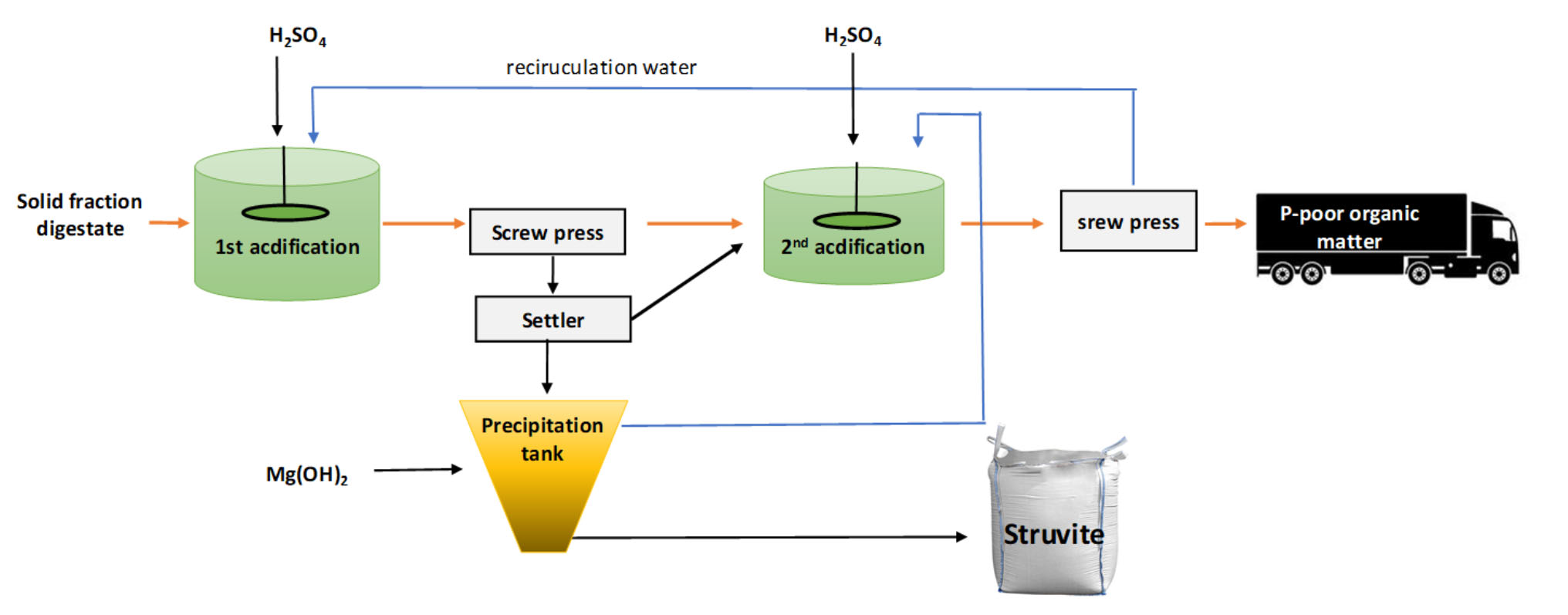

Re-P-eat: Separation of P and organic matter

For the solid fraction, the idea is to process it to a low P solid fraction and a phosphateconcentrate (struvite).

Currently, a pilot installation of this process is operational at Groot Zevert. Nijhuis Industries will start construction of the full-scale installation shortly, based on the concept of Wageningen University & Research (WUR).

WUR developed the Re-P-eat technology, in which different steps of acidifiction of the the solid fraction lead to a solution that is rich in phosphorus.

Subsequent separation with a screw press and adding lime (magnesiumhydroxide) to the liquid fraction renders struvite crystals. These precipitate and are simply recoverd from the liquid fraction. This could be used for the production of mineral or organic fertilisers.

The solid fraction, poor in P because 90% of the inital P is removed, is very well-perceived in the Netherlands, which has strict phosphorus application limits.