Technologies and mass balances

Online calculation tool for cost-benefit analysis of technologies mass- and nutrient balance estimation technology exploration for nutrient recovery from digestate

WEBINAR ON THE USE OF POLYMERS FOR OPTIMIZATION OF DIGESTATE SEPARATION

Technical webinar training on separation of digestate and the use of flocculants organised in the framework of the SYSTEMIC project (22 april 2021).

BIOGAS PLANT DISCUSSIONS ON TECHNOLOGIES

During the “Corona-year” of 2020, the SYSTEMIC biogas plants were invited to weekly online meetings, where different technologies for digestate treatment were discussed with their peers, technology providers and scientists.

This excel file contains the composition of different types of digestate, manure and other feedstocks separation efficiency of liquid-solid separation technologies for digestate recovery rates for NH3 stripping-scrubbing, evaporation, drying, membrane filtration,... the composition of the end products produced after digestate processing technologies

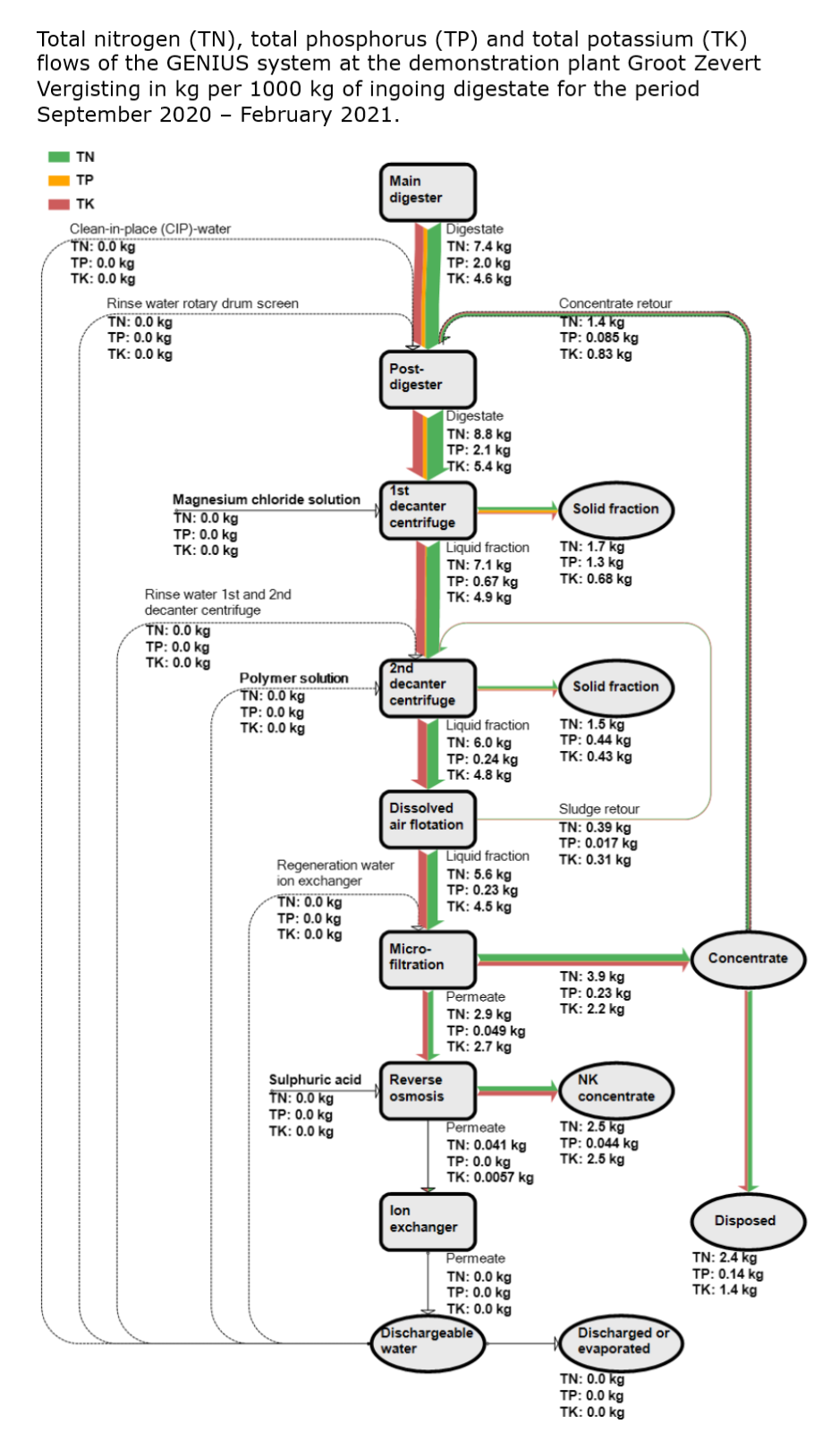

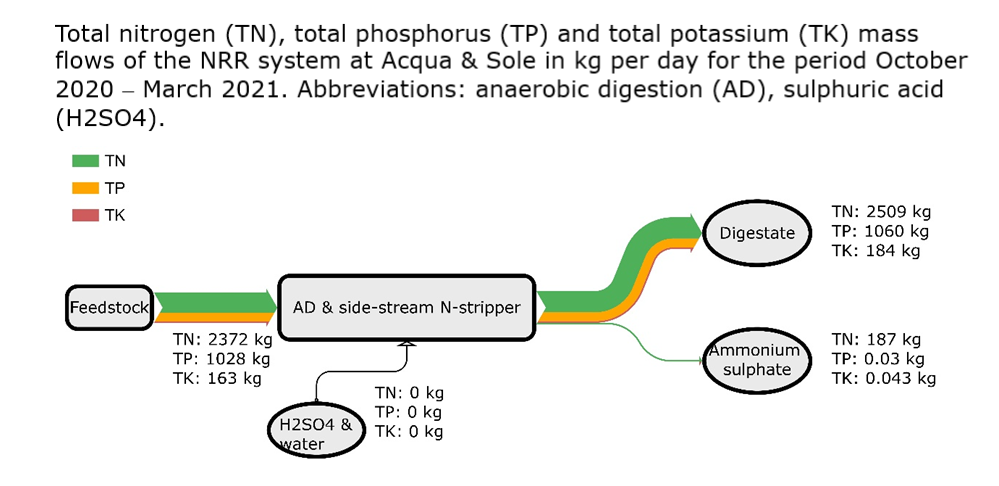

The performance or efficiency of the technology is expressed as the recovery rate. This is defined as the fraction of the initial amount of mass, dry matter, organic matter, nutrients or minerals (N, P, K) that is recovered in the end product.

In the excel, it is found under the blue rows “Recovery rate or separation efficiency (%)”.

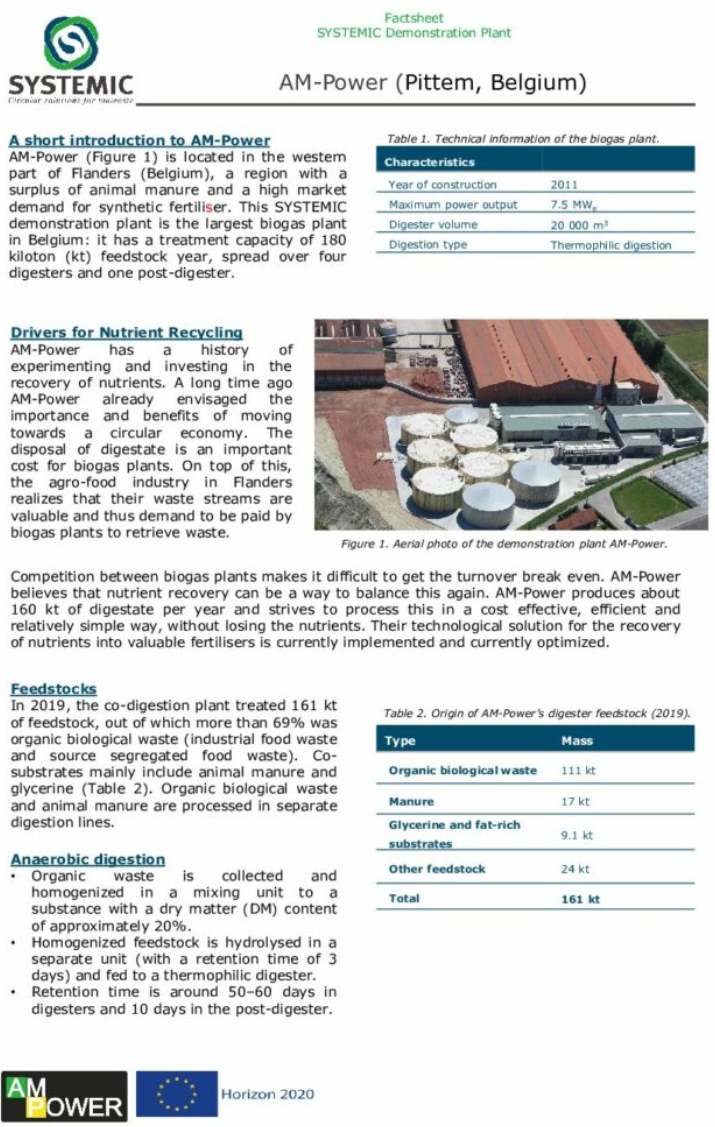

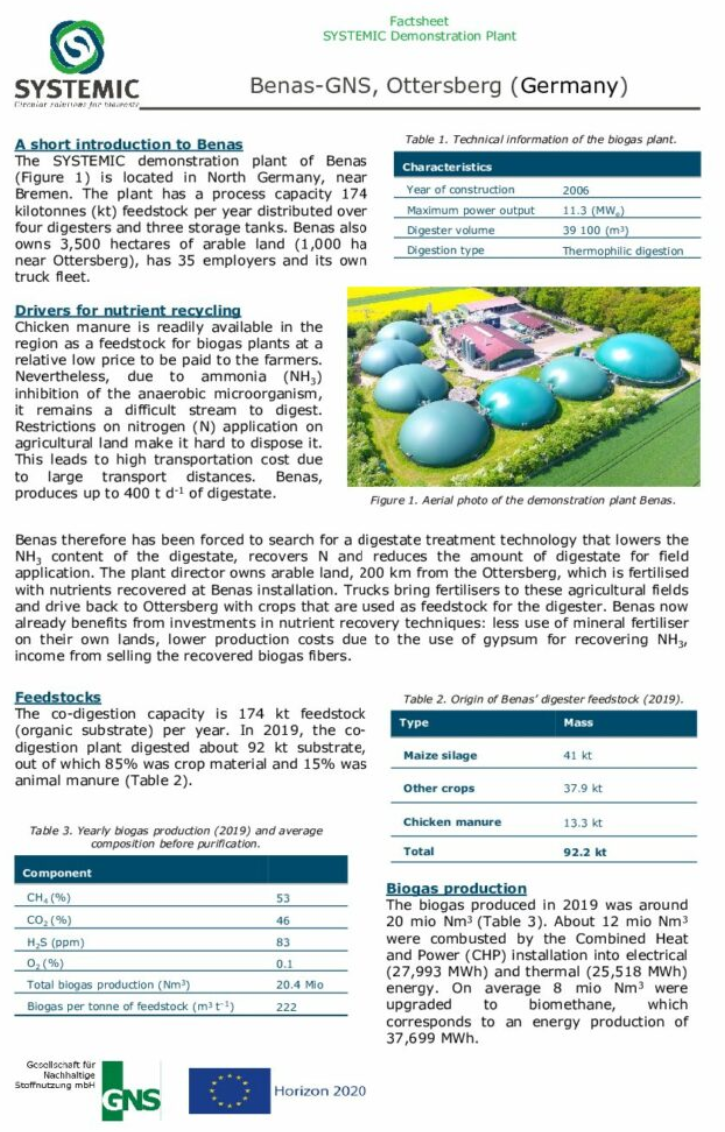

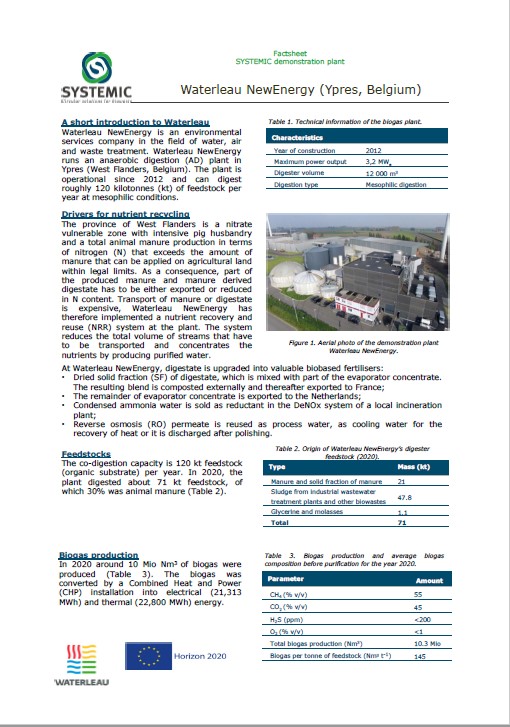

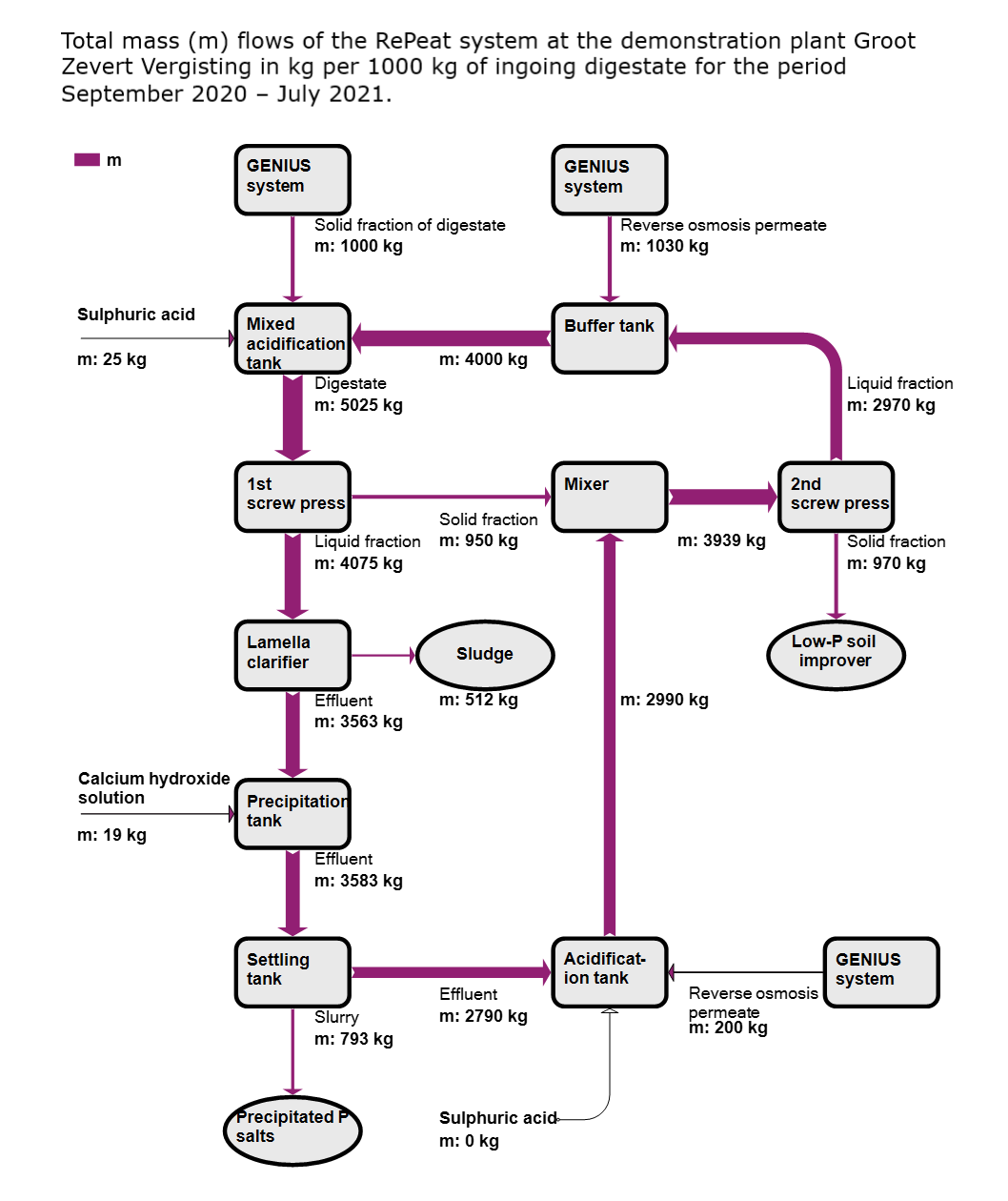

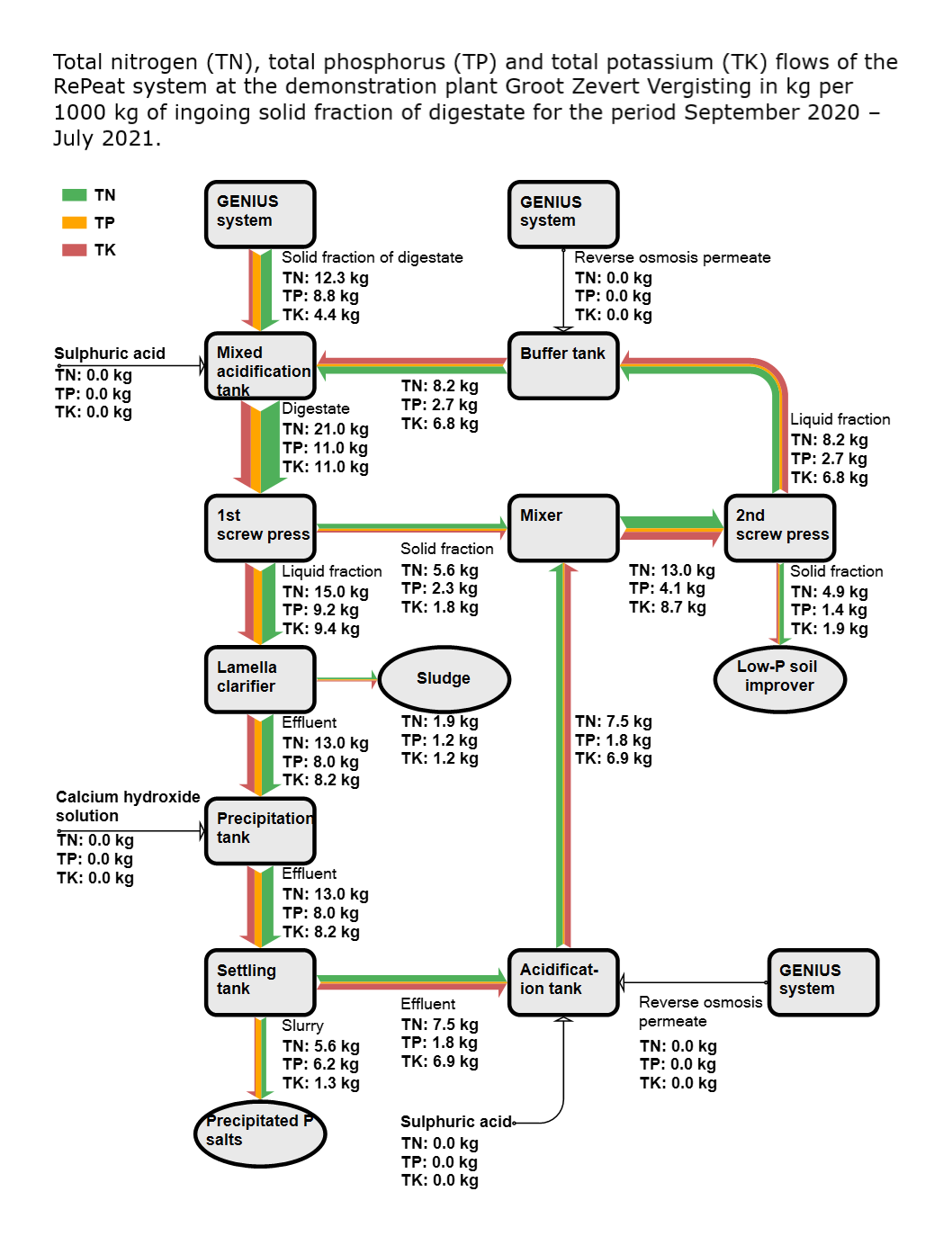

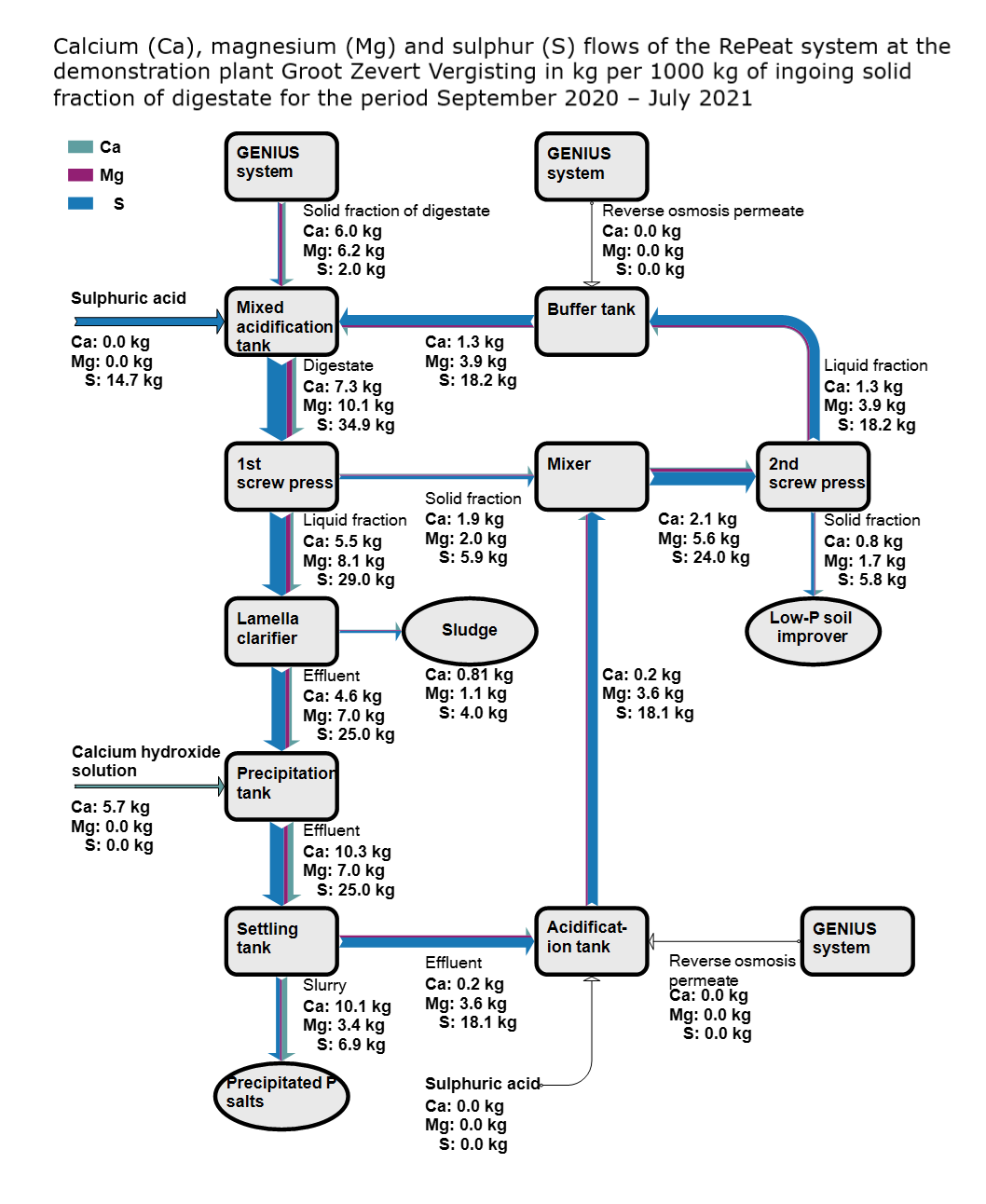

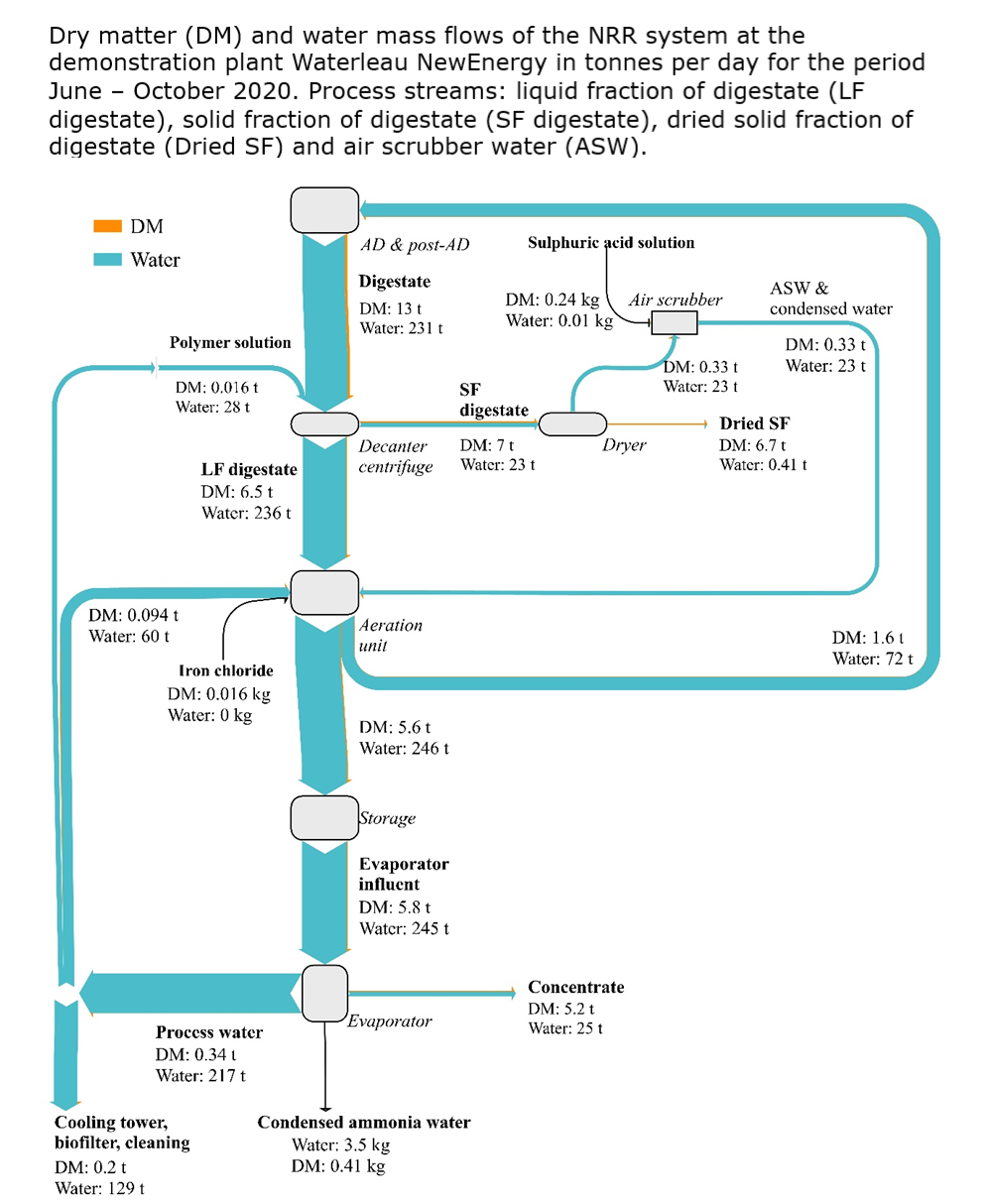

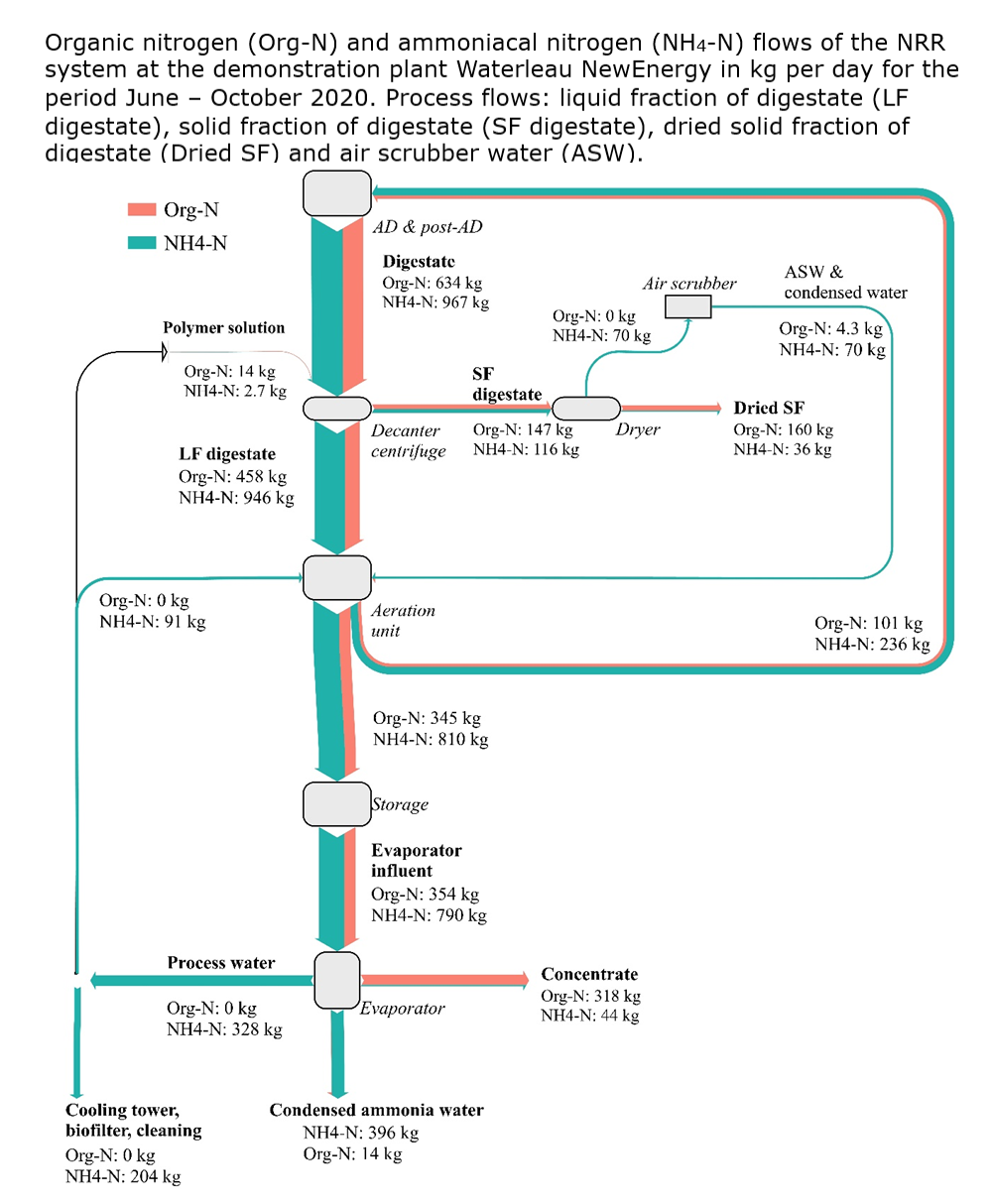

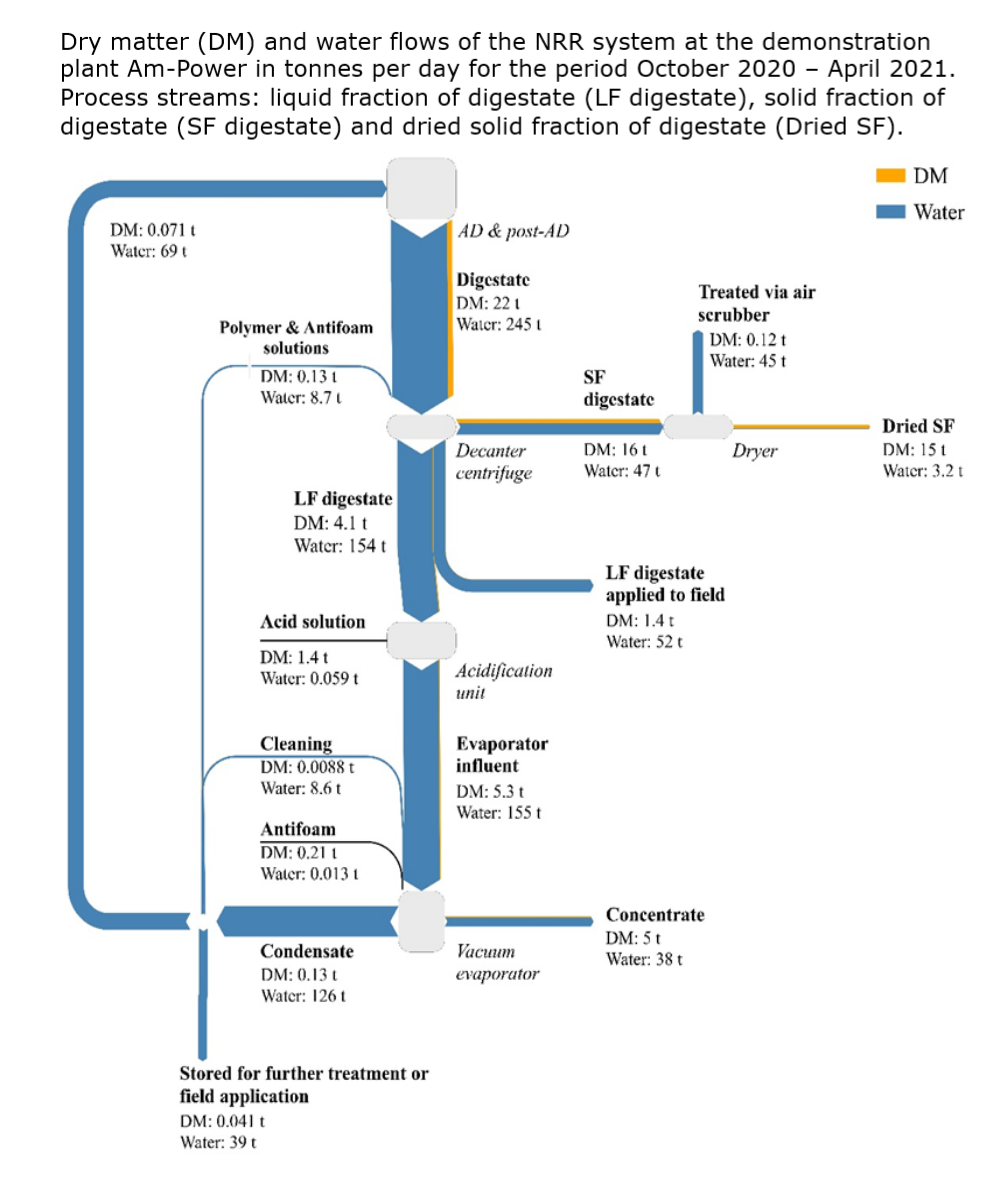

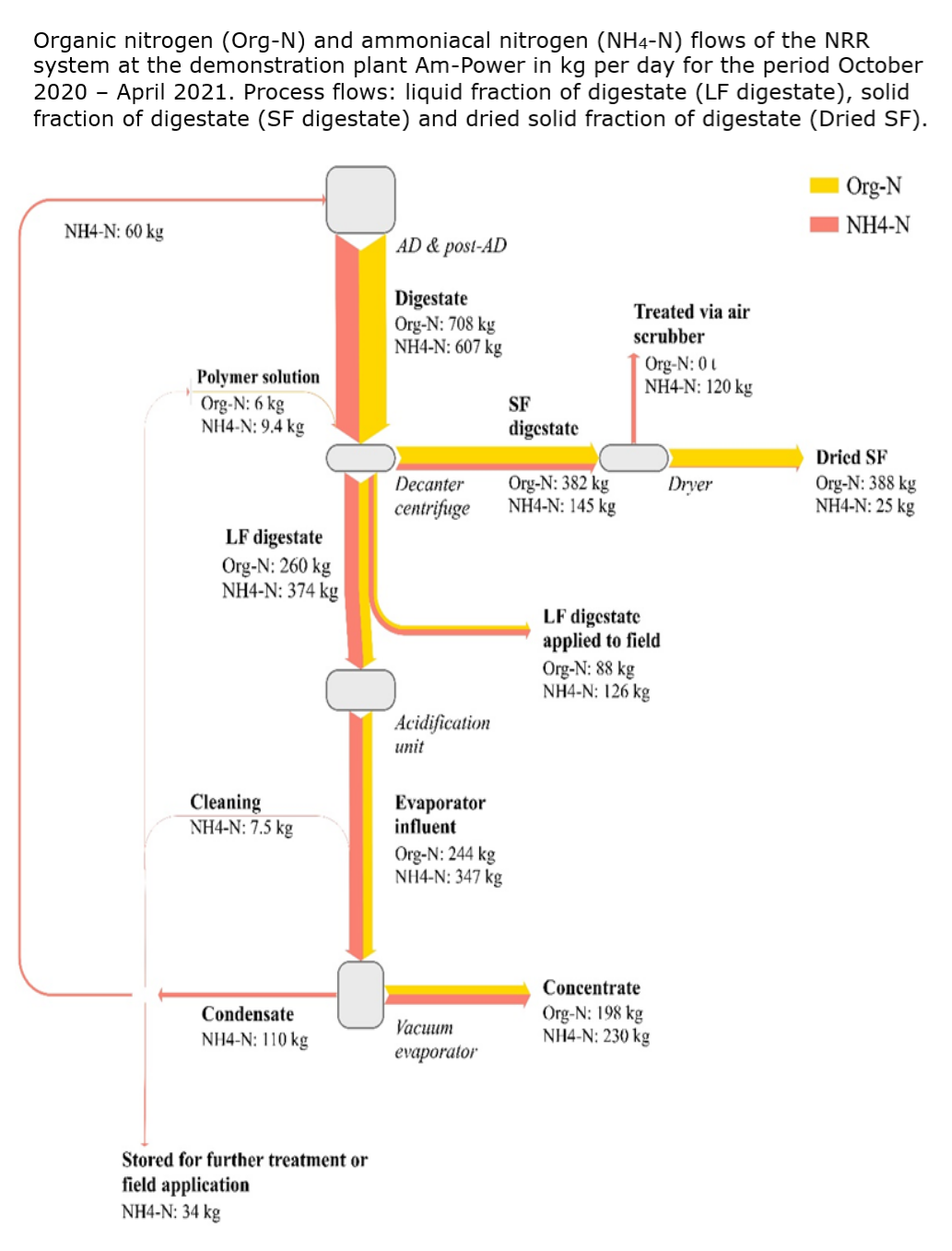

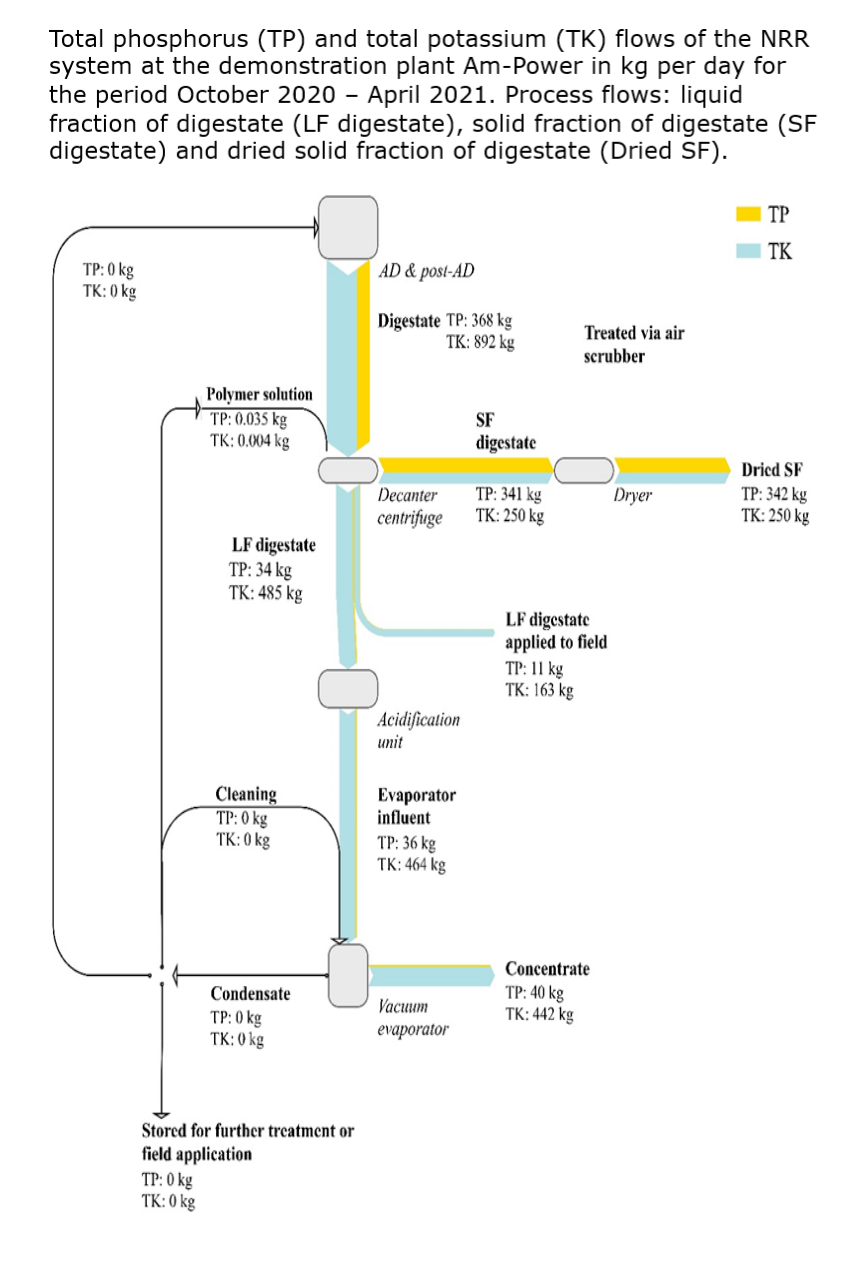

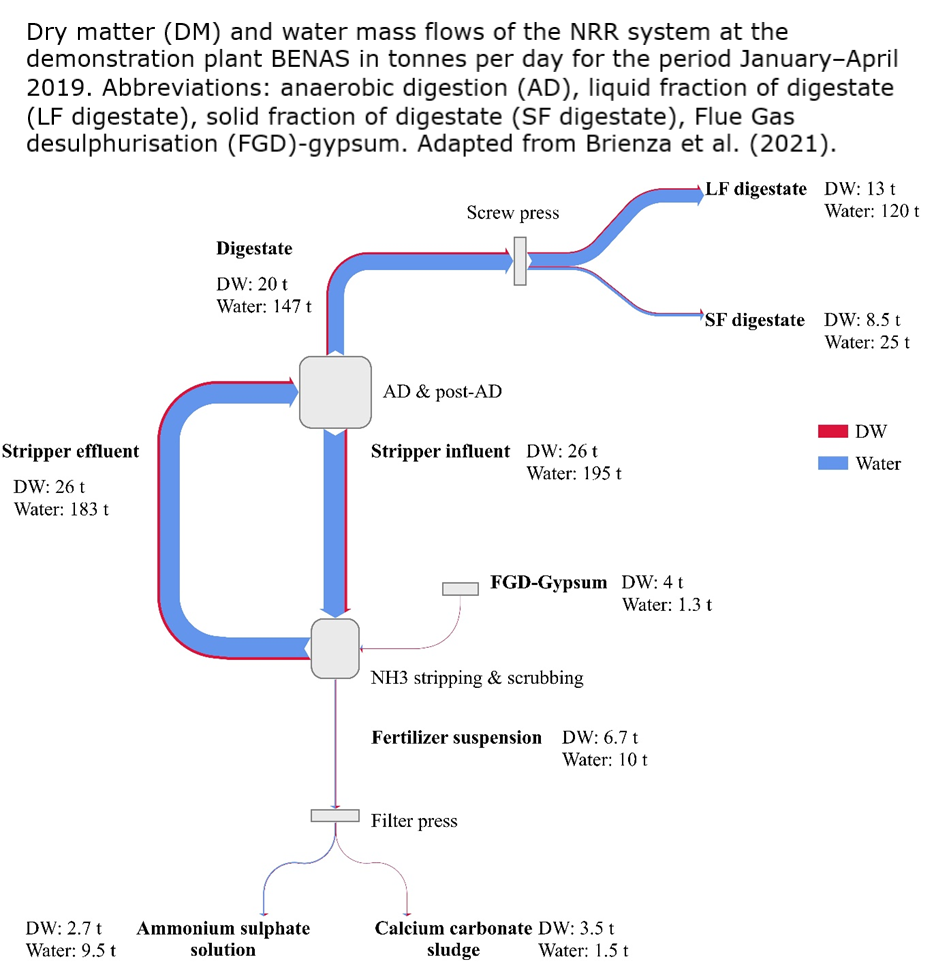

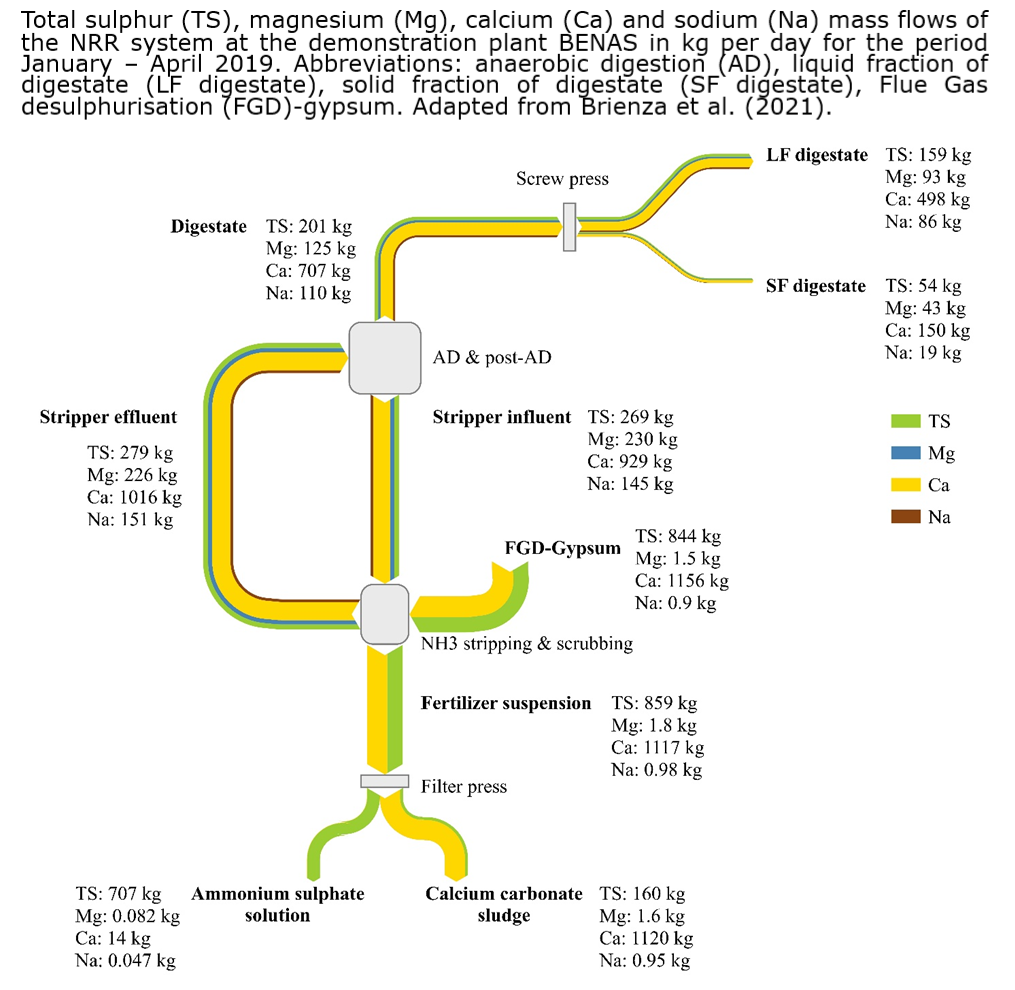

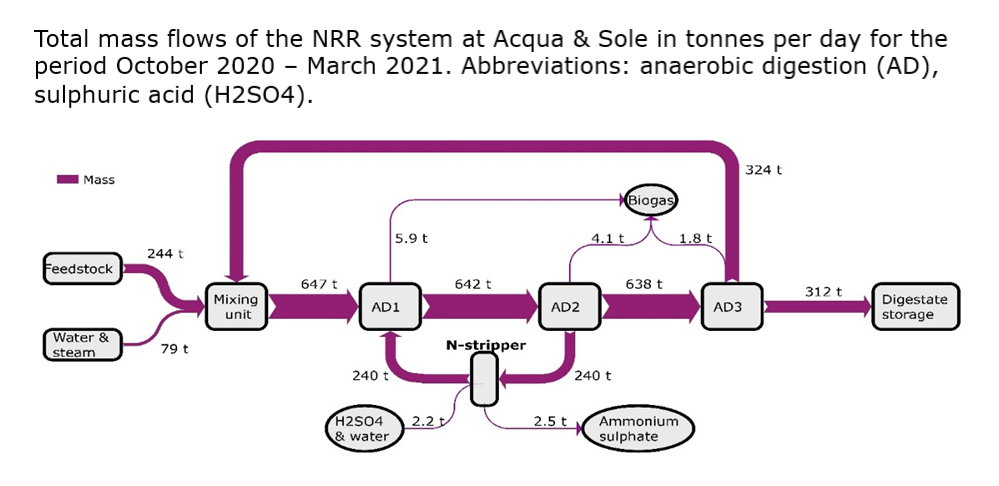

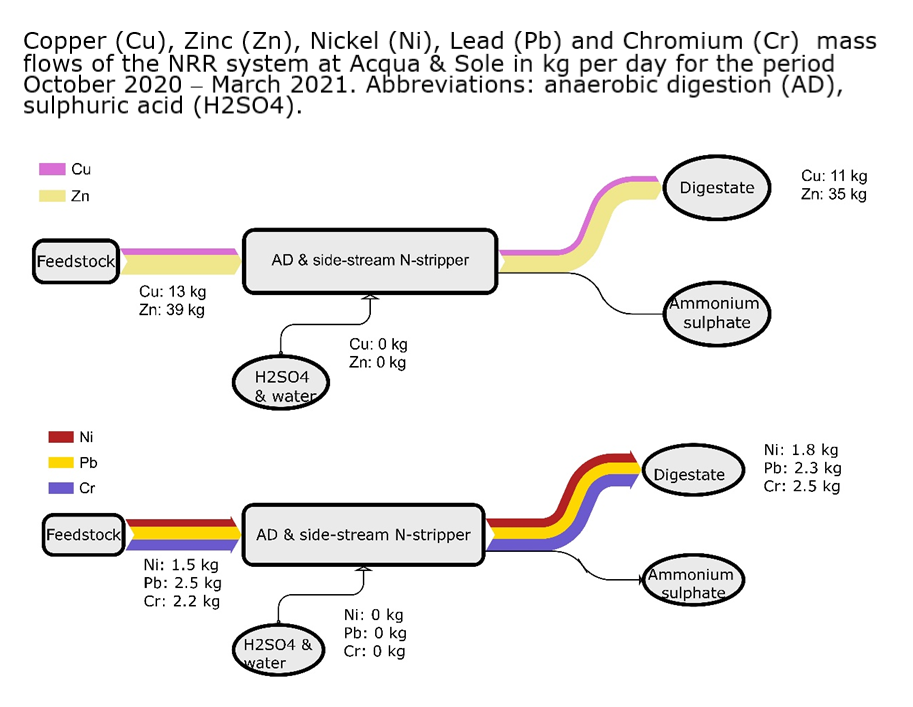

Report: Fourth annual updated report on mass and energy balances, product composition and quality and overall technical performance of the demonstration plants (year 4)

Read all details on the mass balances, energy balances and drivers for nutrient recycling of the 5 Demo Plants in this report.

Per technology, estimations are given for separation efficiency and recovery rate investment costs and operational costs use of chemicals energy requirements surface area

In Content list, you can click on the preferred chapter and the link will take you directly to that part of the document.